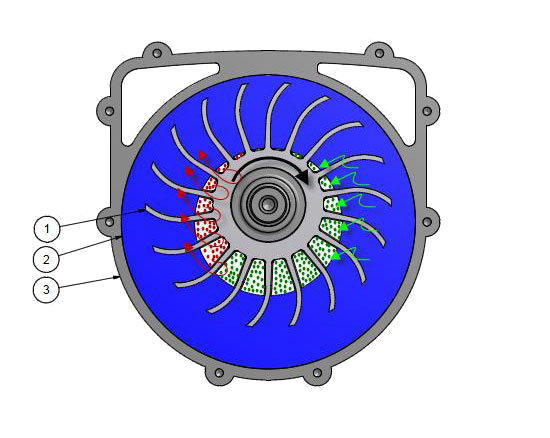

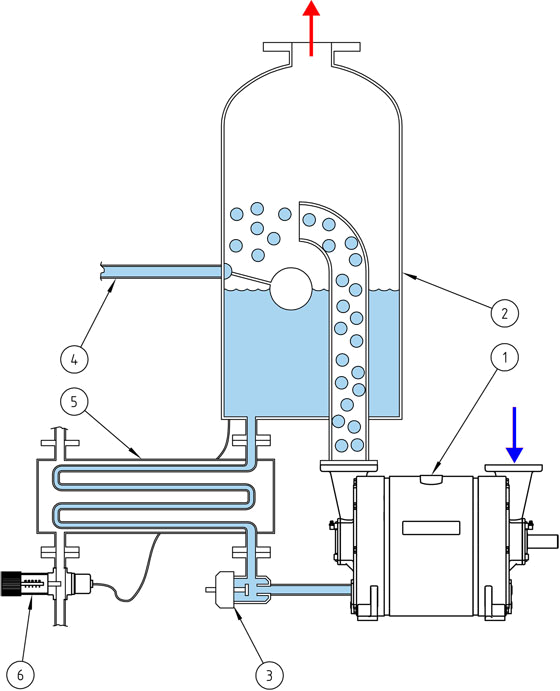

How a liquid ring vacuum pump works

As the name suggests, this type of pump features a liquid ring. There is no mechanical contact between the pump’s moving parts. The liquid acts as small pistons, in much the same way as a traditional piston pump.

Pos 1 : Rotor

Pos 2 : The liquid ring

Pos 3 : Casing

When the pump starts, the liquid ring rotates at the same speed as the rotor.

The rotor is slightly offset from the centre and the liquid ring features an array of small cells. A cell in the uppermost position is completely filled with water.

As the cell turns, a pocket of air is created at the rotor hub.

The liquid acts as a piston as it moves away from the rotor hub to create a suction effect.

As the cell passes the bottom of the chamber, the liquid begins pressing in towards the rotor hub. This causes the air to be forced out of the cell, filling it with liquid ready for the next suction cycle.

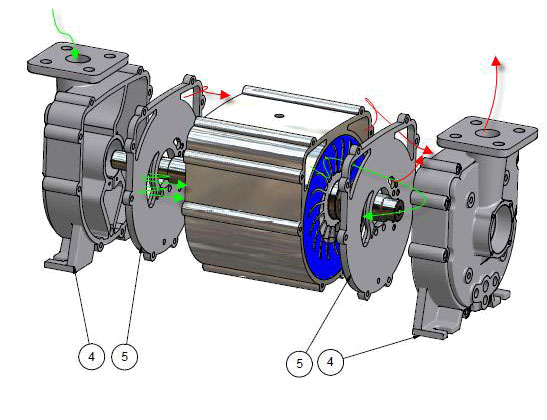

To separate the suction and compression parts of the pump, the ends of the casing are fitted with a flowplates and pumphousing. Some pump types feature connections at both ends, while others (monoblock pumps) only have one at one end of the liquid ring.

Pos 4 : Pumphosing

Pos 5 : Flowplates

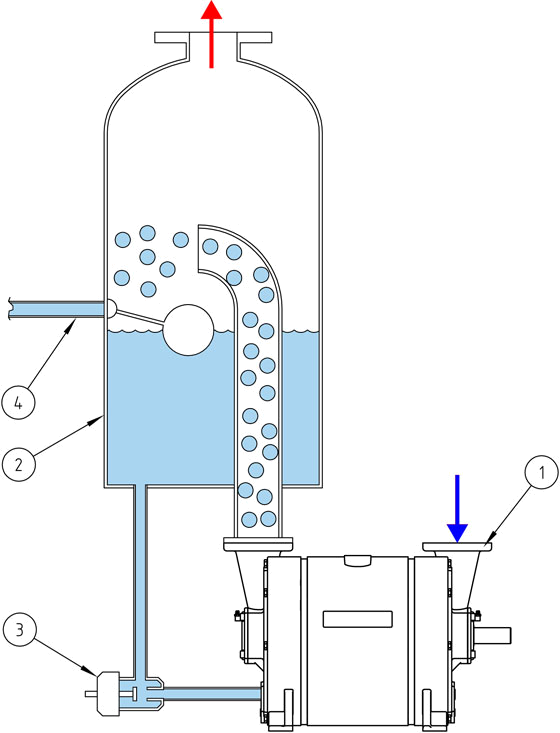

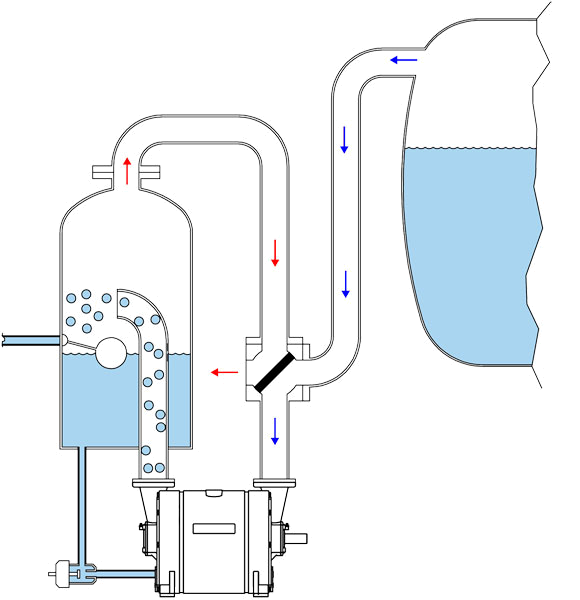

How a liquid separator works

Some of the liquid will be released with the exhaust air. It is therefore necessary to add sealant liquid during operation. To achieve best results while minimising operating costs, we recommend fitting a liquid separator to all our pumps.

As well as collecting and recycling the operating liquid, a liquid separator will ensure correct pump intake pressure.

Pos 1: Liquid ring pump

Pos 2: Liquid separator

Pos 3: Service liquid valve

Pos 4: Service liquid supply

A liquid separator is fitted with a service liquid valve to ensure correct liquid level.

When the service liquid valve is connected to the water supply, it will replace any evaporated liquid.

As the liquid level is above the level of the pump, it is necessary to close the supply of liquid to the pump when it is not running. We have therefore developed a special valve specifically for this purpose. The service liquid valve is opened by pilot pressure created by the liquid ring in the pump. There is therefore no requirement for external control. This valve is listed in our product range under valves.

Cooling

The sealant liquid heats up during operation, so a method of cooling the liquid is therefore often required. Our product range offers three different cooling solutions.

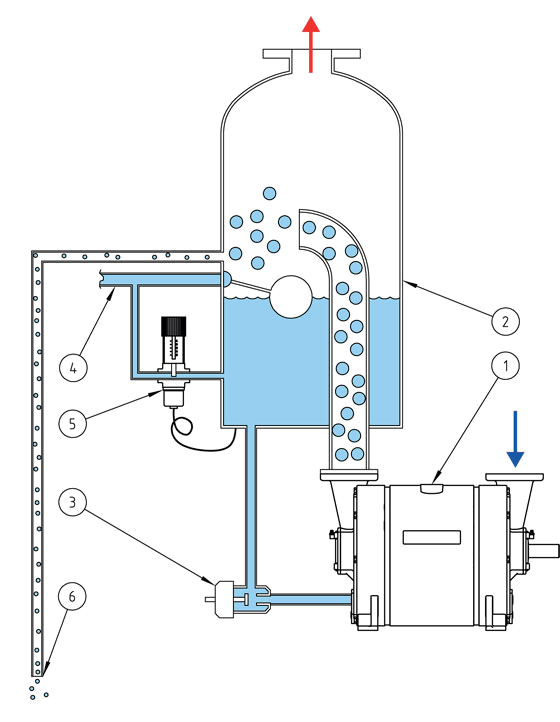

A: Partial recirculation

Cooling by partial recirculation is achieved by replacing part of the service liquid.

A temperature regulating valve ensures that the required amount of water is fed to the liquid separator. The excess hot water flows out of an overflow pipe.

The amount of water consumed depends on the selected water temperature and water supply temperature.

Typically, the amount of water added is between 10 and 20 % of the total water flow.

Pos 1: Liquid ring pump.

Pos 2: Liquid separator.

Pos 3: Service liquid valve.

Pos 4: Service liquid supply.

Pos 5: Temperature regulating valve.

Pos 6: Overflow pipe.

B: Heat exchanger

In instances where access to external cooling water is available, water consumption can be reduced to a few litres per hour. The operating liquid for the pump is fed through a heat exchanger where it is cooled before being fed back into the pump. A temperature regulating valve ensures the correct flow of cooling water for the required temperature.

Pos 1: Liquid ring pump.

Pos 2: Liquid spearator

Pos 3: Service liquid valve.

Pos 4: Service liquid supply.

Pos 5: Heat exchanger.

Pos 6: Temperature regulating valve.

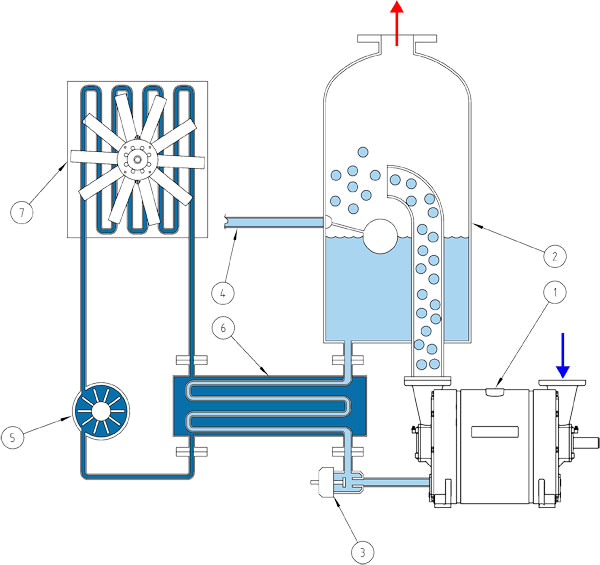

C: Air cooling

Cooling sealant liquid with the aid of an air cooler also minimises water consumption.

The operating temperature is generally slightly higher than that of the above solutions (typically around 20 øC above the ambient temperature).

As the air cooler is sensitive to impurities, the unit includes two cooling circuits.

The hot sealant liquid is fed through a heat exchanger, where it is cooled by the cold water from the air cooler. This means that any impurities drawn through the liquid ring vacuum pump will not be fed through the air cooler.

Pos 1 : Liquid ring pump

Pos 2 : Liquid separator

Pos 3 : Service liquid valve

Pos 4 : Service liquid supply

Pos 5 : Circulator

Pos 6 : Heat exchanger

Pos 7 : Air cooler

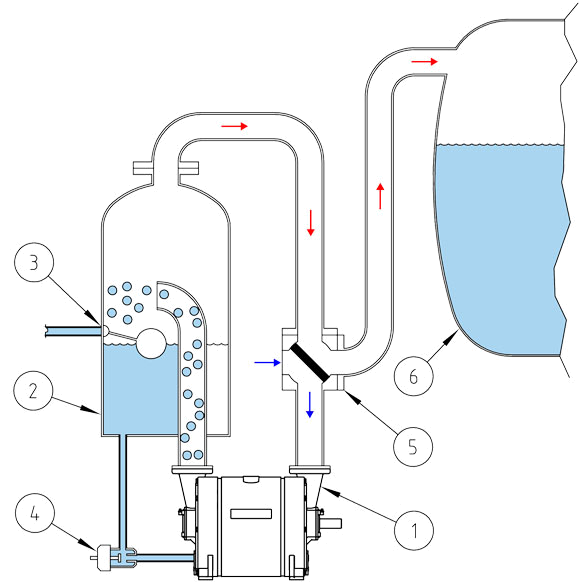

Liquid ring vacuum pump as a compressor

By utilising the compression side of a liquid ring vacuum pump, it can equally well be used as a compressor. The pump can also be connected to a collector tank by fitting a 4-way valve.

The tank is filled when the valve is in the vacuum position and emptied when in the compress position. A 4-way valve can be operated manually or, using an actuator, can be configured to perform an automatic empty/fill cycle.

All of our units can be assembled in this configuration. The relevant accessories are listed in our product range under Components or can be selected when assembling a unit.

Samex – Samson Pumps | Oranjekanaal ZZ 17, 9415 PR, Hijken